TU Delft, FiberCore Europe and Schiphol Logistics Park have given the go-ahead for the realization of a special pedestrian bridge at the logistics business park Schiphol Logistics Park. Never before has it been possible to produce a bridge construction with such sustainable products. The composition of the materials makes the bridge innovative and special. The bridge is expected to be placed in public space in 2017.

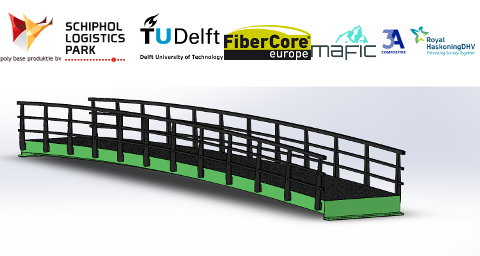

Rafail Gkaidatzis made suggestions for a pedestrian bridge made of as many biobased materials as possible as part of his graduate research at TU Delft. He did extensive research on which materials could be used and their technical and financial feasibility. The so-called bio-basalt-balsa (B3) bridge, 15 meters long and 2 meters wide, will be located between Ringdijkpark and Naritaweg at Schiphol Logistics Park and will be publicly accessible. For example, employees of the business park can use the green park and residents of the adjacent Aalsmeerderdijk can use the bridge to get to the bus stop at Schiphol Logistics Park.

At least 100 years

The bridge deck is produced biobased as much as possible. Basalt fibers and biobased polyester resin are the main raw materials of the bridge deck. Advantages of fiber-reinforced plastic (also called composite) over traditional building materials are their high strength, low energy requirements during construction, low maintenance requirements and long life. In addition to being safe, this also makes it a sustainable building material. The structural properties of the material are not subject to rot or corrosion. As a result, the material is expected to last at least a hundred years, requiring less frequent replacement or maintenance in between.

Basalt fiber is made from the basaltic rock, the volcanic igneous rock created by solidification of lava. The biggest advantage of using basalt fiber over other technical fibers (such as fiberglass) is the strength of the material. Because the fiber is so strong, it requires less material and creates a lightweight bridge. In addition to the strength of the fiber, the material is also completely recyclable. Because it is a volcanic rock, the fiber can be remelted and extracted at an extremely high temperature at the end of the bridge's service life so that the material can be reused.

The resin used for this bridge is partly of natural origin. Polyester resin is made from a reaction of a large number of molecules with both a carboxylic acid and an alcohol group in the molecular chain. To make it, bio-resin glycol derived from vegetable glycerin is used.

FiberCore Europe has extensive experience in building composite bridges, having already delivered a bridge with bio-resin in 2012. In the bridge for Schiphol Logistics Park, even more materials are biobased. It is this combination of materials that makes the project so unique. These materials have never before been used in a bridge construction. They are an important step in making the product more sustainable, thus contributing to the realization of a sustainable society.

Schiphol Logistics Park

Schiphol Logistics Park is a high-quality business park located at one of the most strategic locations in Europe to the south of Schiphol Airport. The location is suitable for both large-scale and small-scale airport-oriented logistics activities due to its location next to the A4 slip road and close to the A5 and A9 motorways. The site is also located directly on the new N201, 5 minutes from Schiphol Airport platforms and also has an excellent 24/7 public transport connection and its own bus stop. Currently located are: Rapid Logistics, Kuehne+Nagel and several smaller logistics entrepreneurs. In the summer of 2016 Interxion (development of Somerset) will open its doors and in the fall of 2016 Expeditors will start the construction of its new premises.

TU Delft

Fascination with science, design and engineering is what drives TU Delft's 21,000 students and 4,700 employees. TU Delft is not only the oldest, but also the largest technical university in the Netherlands. TU Delft cooperates with many other educational and research institutions at home and abroad and is known for the high standard of research and education.

The composite bridge at Schiphol Logistics Park was made possible in part by Mafic S.A., Airex AG (a member of 3A Composites) Royal Haskoning DHV and Poly Base Produktie B.V.