Composite lock gates: the material of the future

Rijkswaterstaat recently published the research results of its study on the materialization of lock doors in the report "MultiWaterWerk: Standardization of Lock Doors. In this report, composite proves its added value as a construction material for lock doors with a very good score on environmental impact (MKI) and lifetime cost (LCC).

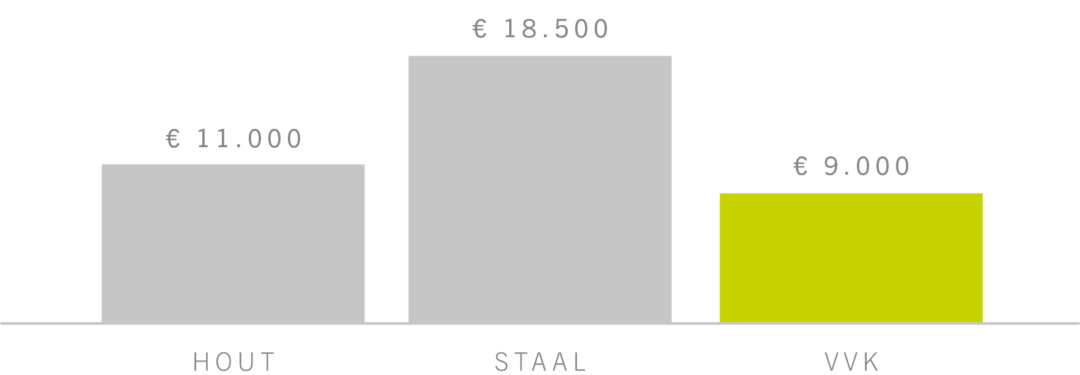

Rijkswaterstaat investigated with the market how the VenR assignment for its 52 locks within project MultiWaterWerken could be carried out efficiently. Rijkswaterstaat had the GWW market carry out a comparative study on the materialization of lock gates. The aim of this study was to find out which material (wood, steel, fiber-reinforced plastics or hybrid) would score best in terms of environmental impact and lifetime costs for certain sizes of doors. As market leaders, Royal HaskoningDHV and FiberCore Europe focused on the material fiber-reinforced plastics (VVK, or composite).

Unique design tool

Jan Kroon, Managing Director of FiberCore Europe: "In order to find the optimal combination of LCA and LCC for different lock door sizes, Royal HaskoningDHV has developed a wonderful tool. This tool makes it possible to design an optimal and material-efficient lock gate for each lock dimension and water level that meets the applicable standards and has a minimum MKI value."

Many material-specific advantages

A composite sluice gate does not need to be removed for major maintenance during its 100-year service life and therefore has the highest availability of any material. A lightweight spare door is therefore sufficient, saving costs and materials. Due to the light weight of the doors, existing pivot points can be reused. The great design freedom of composite makes modifications to the lock head unnecessary.

The research (reviewed by Nibe and Kodos) shows that VVK lock gates have a very favorable MKI value. The same applies to the LCC costs (construction and maintenance for 100 years).